3 3: Equivalent Units Weighted Average Business LibreTexts

It can help to ensure that the calculation is precise and simple for stakeholders to understand. Regular inventory counting is necessary to determine the number of goods in progress and finished goods on hand. It can help ensure that all units are accounted for and prevent over- or under-reporting of equivalent production units.

Which of these is most important for your financial advisor to have?

Add them to the really completed units to get 750,000 units, which represents the number of equivalent whole units you have produced. It’s a lot easier to talk about a whole unit than some whole units and some partially completed units. At the start of an accounting period a business has 2,000 units in beginning work in process. During the accounting period a further 8,000 units are added to the production process and 6,000 units are completed and transferred out, leaving an ending balance of 4,000 units in work in process. Equivalent units of production are used by a manufacturer to express partially completed units of product in terms of finished units. To accurately compare equivalent production units over time, companies should use consistent units of measure.

How To Calculate Equivalent Units of Production

To measure output accurately, these partially completed units must be considered in the output computation. Equivalent or effective units of production represent the production subject to change 2020 of a process expressed in terms of completed units. The next step is to convert the physical units in production shown above (10,000) into equivalent units.

Step Four: Allocating the Costs to the Units in the Finishing Department

- Regular analysis and review of the calculation of equivalent production units can help identify errors and inconsistencies and enable companies to make necessary adjustments.

- We may earn a commission when you click on a link or make a purchase through the links on our site.

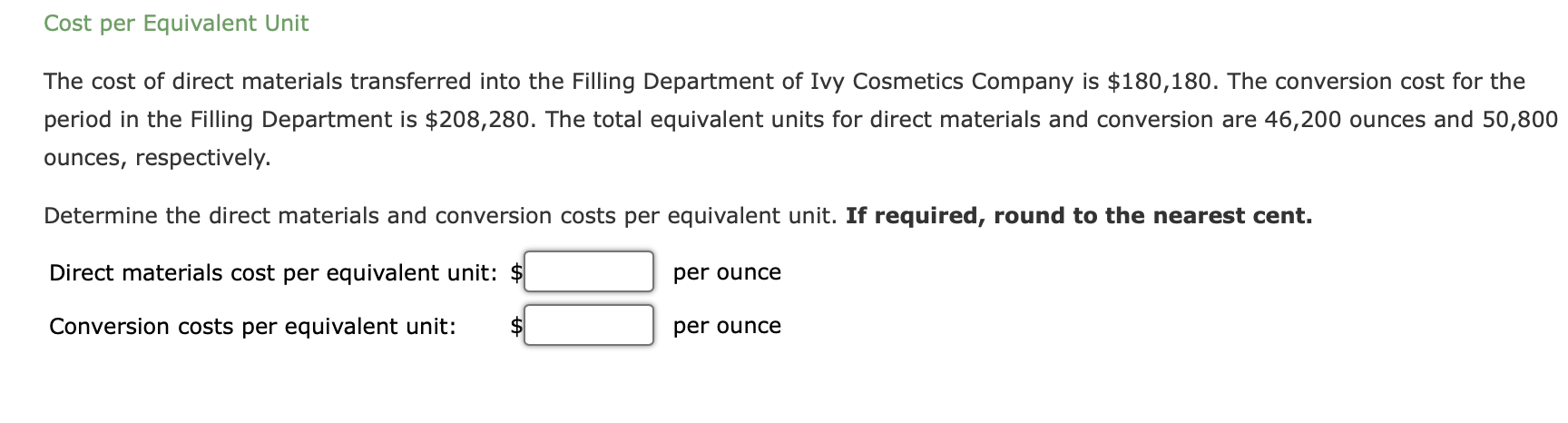

- In this example, the Cost Per Equivalent Unit is $7, indicating the cost allocated to each equivalent unit produced.

- Equivalent or effective units of production represent the production of a process expressed in terms of completed units.

Actual units produced is a simpler method, as it only requires tracking the number of fully completed units. The calculation of EUP requires conversion factors to determine the equivalent number of completed units. These conversion factors are often based on assumptions and estimates and may not accurately reflect the work done at each production stage. Thirdly, the equivalent units of production for the closing work-in-progress should be determined by considering the number of units of closing work-in-progress and the level of completed work. The output of a department is always stated in terms of equivalent units of production. Although 25 percent of the units are unfinished, in “equivalent unit talk” you can treat them as 150,000 completed units.

Finance Strategists is a leading financial education organization that connects people with financial professionals, priding itself on providing accurate and reliable financial information to millions of readers each year. At Finance Strategists, we partner with financial experts to ensure the accuracy of our financial content. For information pertaining to the registration status of 11 Financial, please contact the state securities regulators for those states in which 11 Financial maintains a registration filing. Finance Strategists has an advertising relationship with some of the companies included on this website. We may earn a commission when you click on a link or make a purchase through the links on our site.

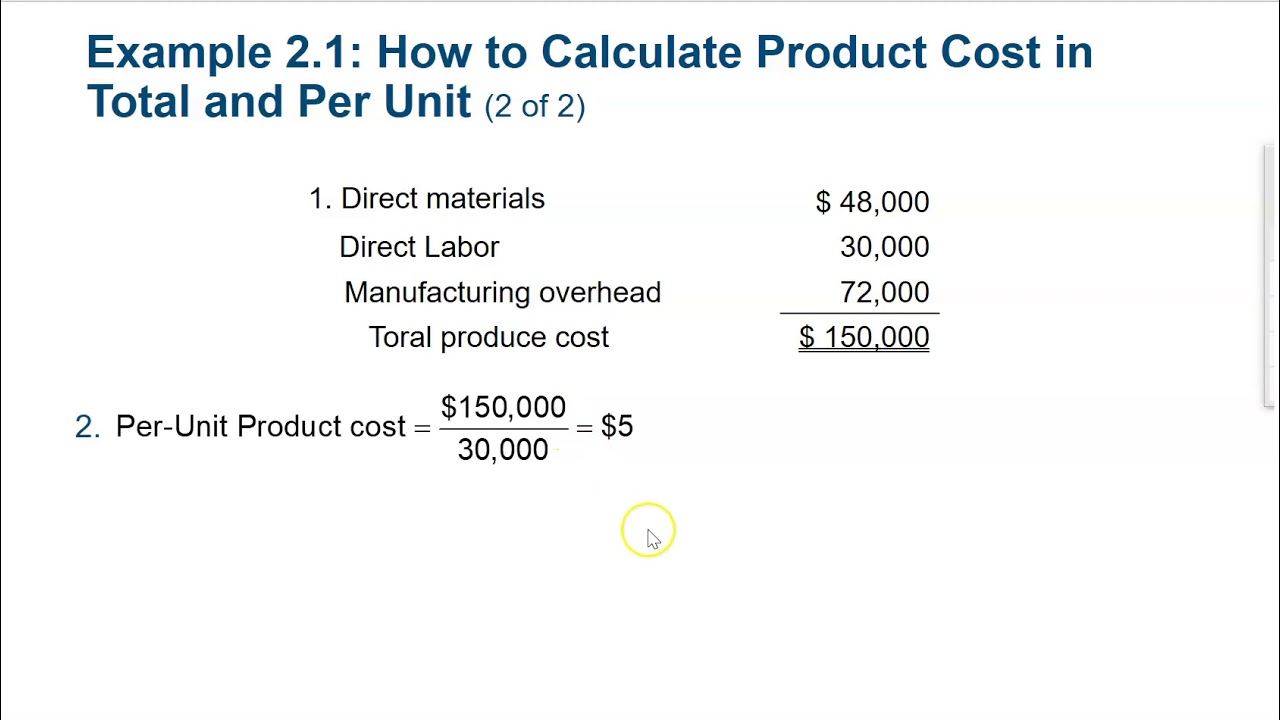

Physical Units

For example, calculating equivalent production units may involve different costs, such as direct materials, direct labor, and manufacturing overhead in the manufacturing industry. In this case, the equivalent production units for each cost type may be calculated separately and then added together to obtain the total equivalent units for the period. For the shaping department, the materials are 100% complete with regard to materials costs and 35% complete with regard to conversion costs. The 7,500 units completed and transferred out to the finishing department must be 100% complete with regard to materials and conversion, so they make up 7,500 (7,500 × 100%) units. The 1,200 ending work in process units are 100% complete with regard to material and have 1,200 (1,200 × 100%) equivalent units for material. The 1,200 ending work in process units are only 35% complete with regard to conversion costs and represent 420 (1,200 × 35%) equivalent units.

As you examine the diagram, think of the amountof water in the glasses as costs that the company has alreadyincurred. Under the weighted average method, we use beginning work in process costs AND costs added this period. EUP is calculated over a specific period, usually a month or a quarter, while actual units produced refer to the total number of finished goods produced up to a specific point. EUP helps businesses accurately measure their production output, which is essential for accurate financial reporting.

Overall, understanding EUP is essential for manufacturing and production businesses looking to control costs, increase efficiencies, and improve profitability. By tracking EUP, managers can make more informed decisions about allocating resources and managing inventory, ultimately leading to a more prosperous and profitable business. Manufacturers can make informed decisions about production scheduling and inventory levels by tracking the number of units in each stage of the production process. For example, if we bring 1,000 unitsto a 40 % state of completion, this is equivalent to 400 units(1,000 x 40%) that are 100% complete. Accountants base this concepton the supposition that a company must incur approximately the sameamount of costs to bring 1,000 units to a 40% level of completionas it would to complete 400 units. Once the cost per EU is calculated, the costs are allocated to the goods that were partially finished and completely finished during the period.